Application

Thermoelectrics

Thermoelectric materials, which can generate electricity from waste heat or be used as solid-state Peltier coolers, could play an important role in a global sustainable energy solution. Fundamentals to the field of thermoelectric materials is the need to optimize a variety of conflicting properties. To maximize the thermoelectric figure of merit (ZT) of a material, large Seebeck coefficient (α), high electrical conductivity (σ), and low thermal conductivity (κ) are required. As these transport characteristics depend on interrelated material properties, a number of parameters need to be optimized to maximize ZT.

High ZT values are necessary for the high conversion efficiency (η) of the thermoelectric generator. The conversion efficiency is the ratio between the electric output power (P) and the heat input (Qh).

So far, various strategies have been suggested to increase ZT values of TE materials. However, despite recent improvements in the efficiency of TE materials, the device engineering of TE modules has been largely neglected by strictly limited processing methods to fabricate devices. As a solution of this challenge, we develop the inks of thermoelectric materials and processing to architecture TE materials in 2D and 3D.

Thin film fabrication of thermoelectric system offers new scope for ZT enhancement by tailoring microstructure, which are determined by interface and strain energy at the forming stage of the thin film. This offers a wide range of ways to control texturing and doping in thin films through the choice of substrates, the coating process and the manipulation of post-treatment conditions. Also, thermoelectric thin films are potentially useful for various applications such as micro-Peltier-coolers, micro-generators, and miniature sensors as well as flexible TE power supply. Furthermore, thermoelectric ink can be directly painted onto curved heat sources, minimizing heat loss which essentially increases the efficiency of thermoelectric module. Especially, 3D printing technology enable us to shape thermoelectric materials conformable to free-form heat sources, which will maximize the heat transfer to thermoelectric devices. Furthermore, this 3D printing process can not only minimize the abandoned materials, but also reduction of process steps, which are the issues of conventional manufacturing.

The specific materials of interest for adopting the 3D printing technology are based on metal chalcogenide that have a wide temperature range from room temperature to high temperature operation with high thermoelectric efficiency.

Relevant publication:

– Heo, et al. Thin Film and Flexible Thermoelectric Generators, Devices, and Sensors. Springer, 2021, Part I-3. Solution-Processed Metal Chalcogenide Thermoelectric Thin Films.

– Jo, et al. Soluble Telluride-Based Molecular Precursor for Solution-Processed High-Performance Thermoelectrics. ACS Appl. Energy Mater.. 2019, 2, 4582-4589

– Heo, et al. Composition change-driven texturing and doping in solution-processed SnSe thermoelectric thin films. Nature Commun. 2019, 10, 864.

– Eom, et al. Rheological design of 3D printable all-inorganic inks using BiSbTe-based thermoelectric materials. J. Rheol. 2019, 63, 291.

– Jo, et al. Ink processing for thermoelectric materials and power generating devices. Adv. Mater. 2018, 1804930.

– Kim, et al. 3D printing of shape-conformable thermoelectric materials using all-inorganic Bi2Te3-based inks. Nature Energy 2018, 3, 301-309.

– Gu, et al. Colloidal Synthesis of Te-doped Bi Nanoparticles: Low-Temperature Charge Transport and Thermoelectric Properties. ACS Appl. Mater. Interfaces 2017, 9, 19143.

– Park, et al. High performance shape-engineerable thermoelectric painting. Nature Commun. 2016, 7, 13403.

– Jo, et al. Simultaneous improvement in electrical and thermal properties of interface-engineered BiSbTe nanostructured thermoelectric materials. J. Alloy. Compd. 2016, 689, 899.

Electronics

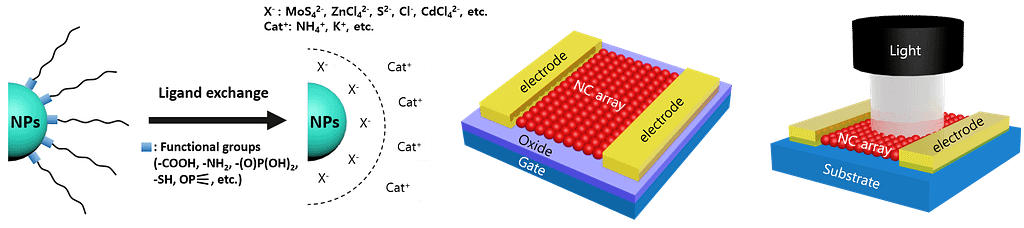

Based on this technology, we are expanding the versatility of our designed inorganic inks thorough combination of a broad range of NCs and functional inorganic precursors as well as a concept that NCs are embedded in a semiconductor thin film.

Relevant publication:

– Donzhnikov, et al. Composition-matched molecular “solders” for semiconductors. Science. 2015, 347, 425-428.

– Jang, et al. Temperature-Dependent Hall and Field-Effect Mobility in Strongly Coupled All-Inorganic Nanocrystal Arrays. Nano Lett. 2014, 14, 653-662.

Catalyst

Relevant publication:

– Choi, et al, Thiometallate precursors for the synthesis of supported Pt and PtNi nanoparticle electrocatalysts: Size-focusing by S capping. Nanoscale 2021, 3, 517.

– Jeong, et al, Transition Metal-Based Thiometallates as Surface Ligands for Functionalization of All-Inorganic Nanocrystals. Chem. Mater. 2017, 29, 10510-10517.